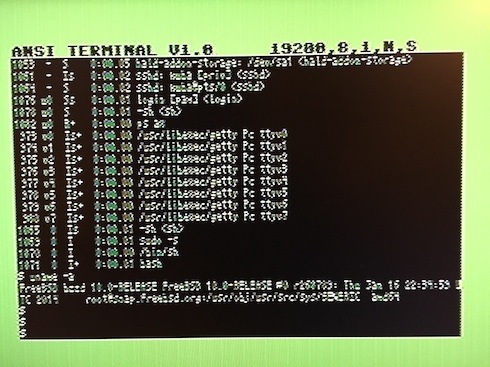

I’ve always been a big fan of serial ports, modems and especially computer-to-computer null-modem communication,

I wanted my Commodore 64 to be able to serve as a serial terminal, but the built-in serial port has extremely low speed.

I found this project, called UART Cartridge, and I knew this is it, of course those carts are not possible to buy, I had to make them myself, so I got to work.

I’ve ordered the PCB’s, all the parts (some still haven’t arrived so I had to find alternative source), and built the first cart already.

The result is amazing, the cart looks great and works really well as well.

I’ve been using my C64 on a Dell U2410 monitor over Composite cable, and the result wasn’t very good,

as much as games look okay scaled, the small very sharp font doesn’t stretch well, so I had to look for other solutions.

First, I tried Japan-made EntaVision S-Video->VGA converter, with mixed results, the font is more readable but somehow it doesn’t handle interlacing well and everything looks jittery.

Then, I tried “UP Empire SD-CSH1” S-Video -> HDMI converter and the result is much better, the font is very readable, although on my Monitor I can’t adjust the 720p/1080p picture to 4:3 aspect ratio, well, with such a small font it might be even better to keep it stretched – makes it even more readable.

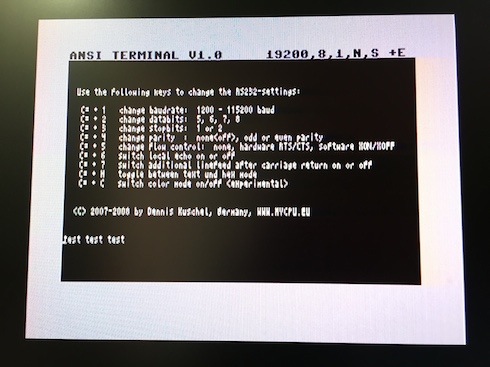

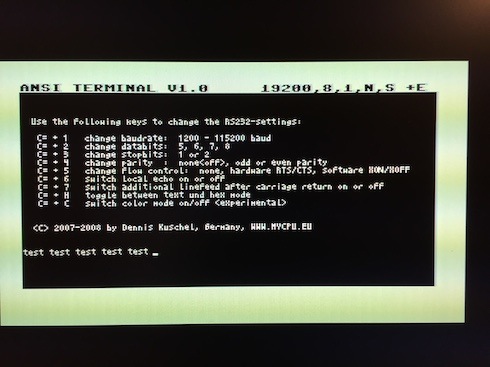

The schematics and design was done by Dennis Kuschel, and are available on his website:

http://mycpu.selfhost.it/otherprojects/c64terminal/index.htm

I have enough parts to make a few more of those carts (and another part order pending), and will happily do so if you’re interested.

I would ship from Japan, it seems that worldwide shipping ranges between $4 and $8 depending on the speed.

Please contact me if you’d like to place an order (for tracking purposes I would recommend registering on my blog and placing a comment – also that other folks can see what is the demand).

Cost for a single unit : $40

Cost for 2-5 units: $35 each

Waiting time from placing an order to shipment – 2-4 weeks (although I will try to keep a small stock of ready-made carts or at least part sets for immediate assembly).

Please note that *your* cartridge may look different, due to supply of certain parts, some of them may be substituted for others.

The cartridges are fully tested on a PAL (EU) Commodore 64.

I have verified that the software itself works on an NTSC Commodore 64 with help of an emulator (VICE), there is no 100% guarantee that it will work on an actual NTSC C64 – and I will not accept returns should that be the case.